Reticulated Polyurethane Foam Vs Nano Polyurethane

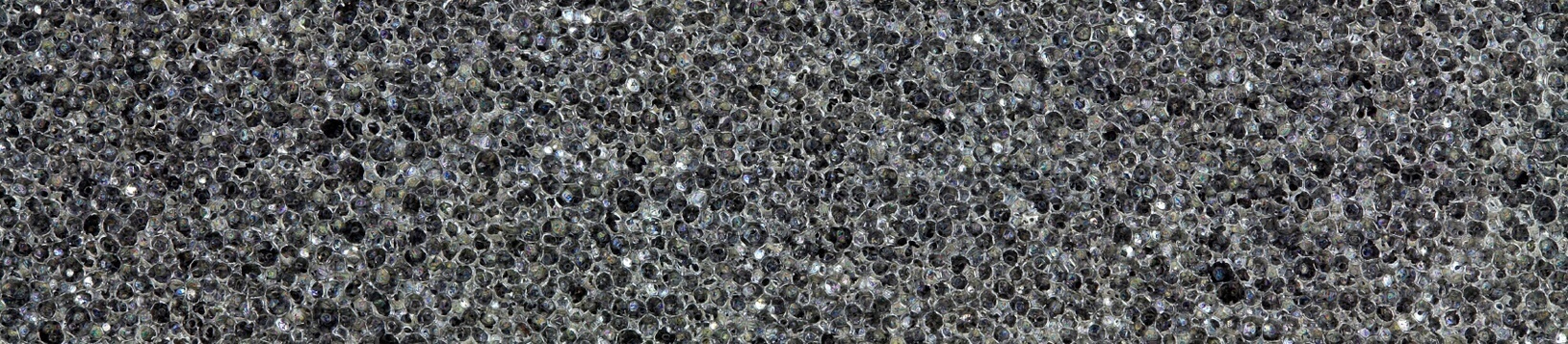

Polyether reticulated foam is a compressed open cell smooth type of polyurethane foam that allows moisture and air to easily navigate through its cell structure.

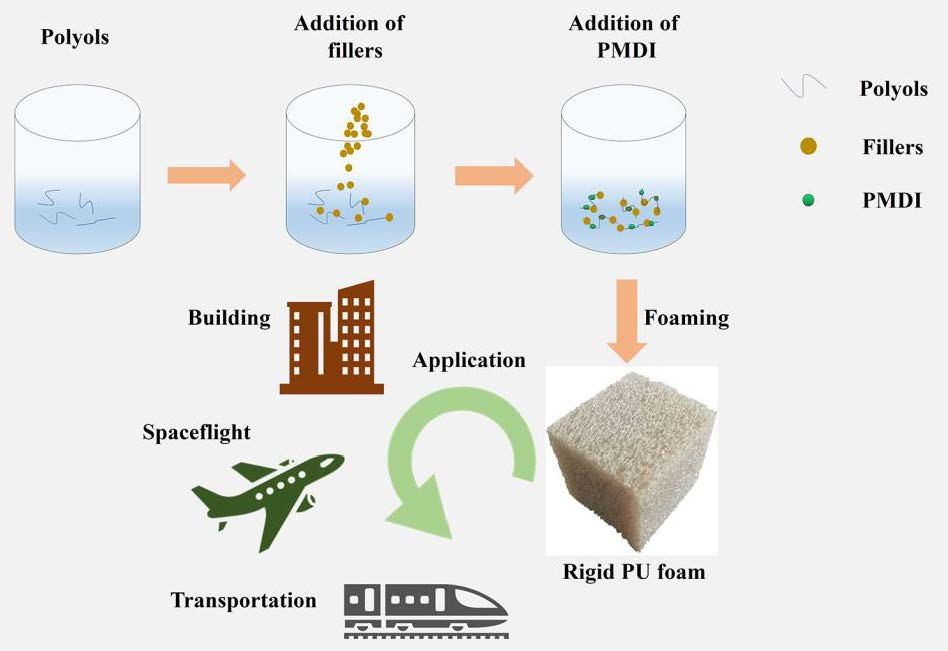

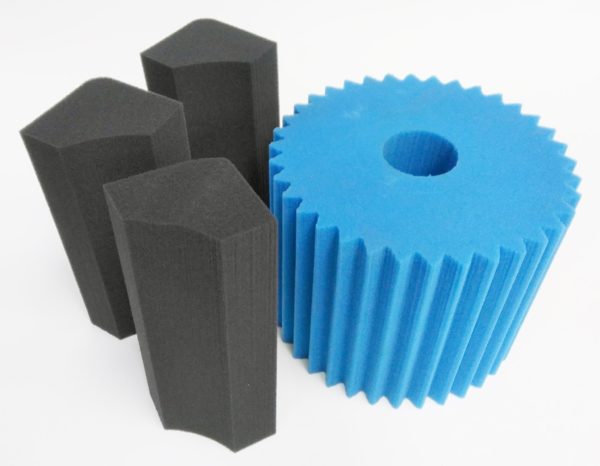

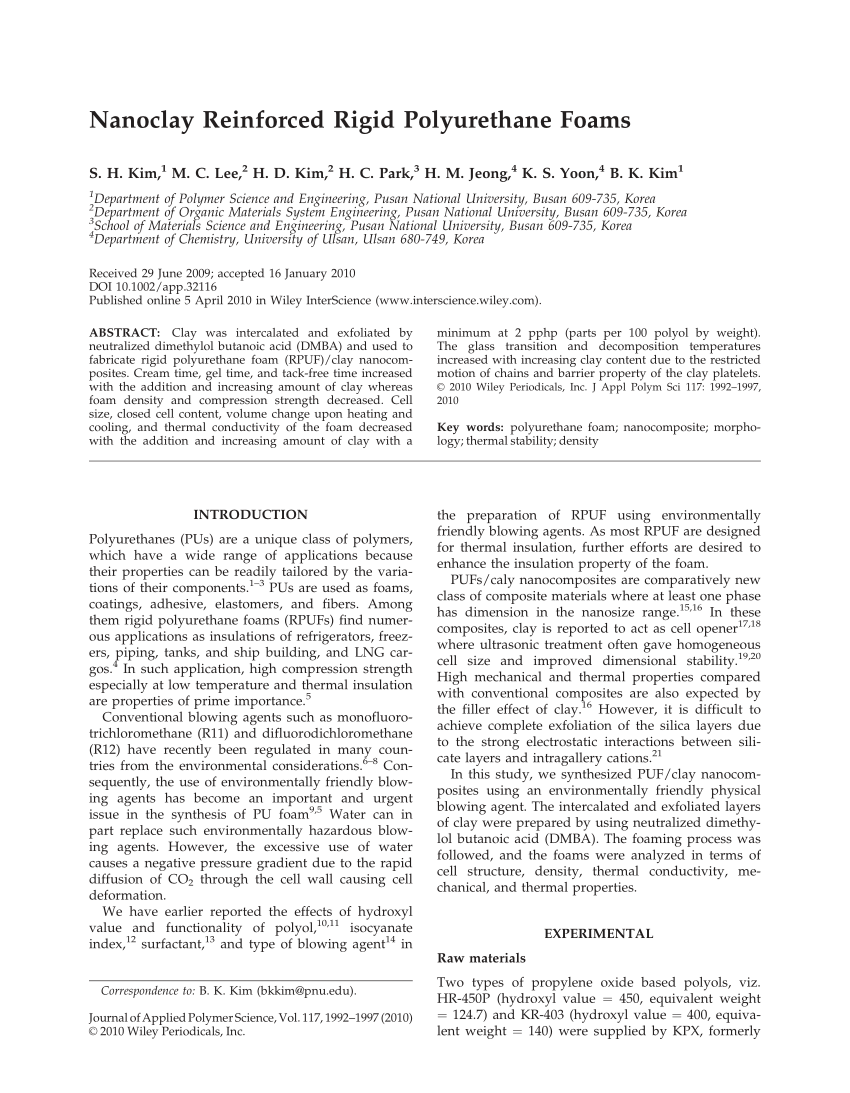

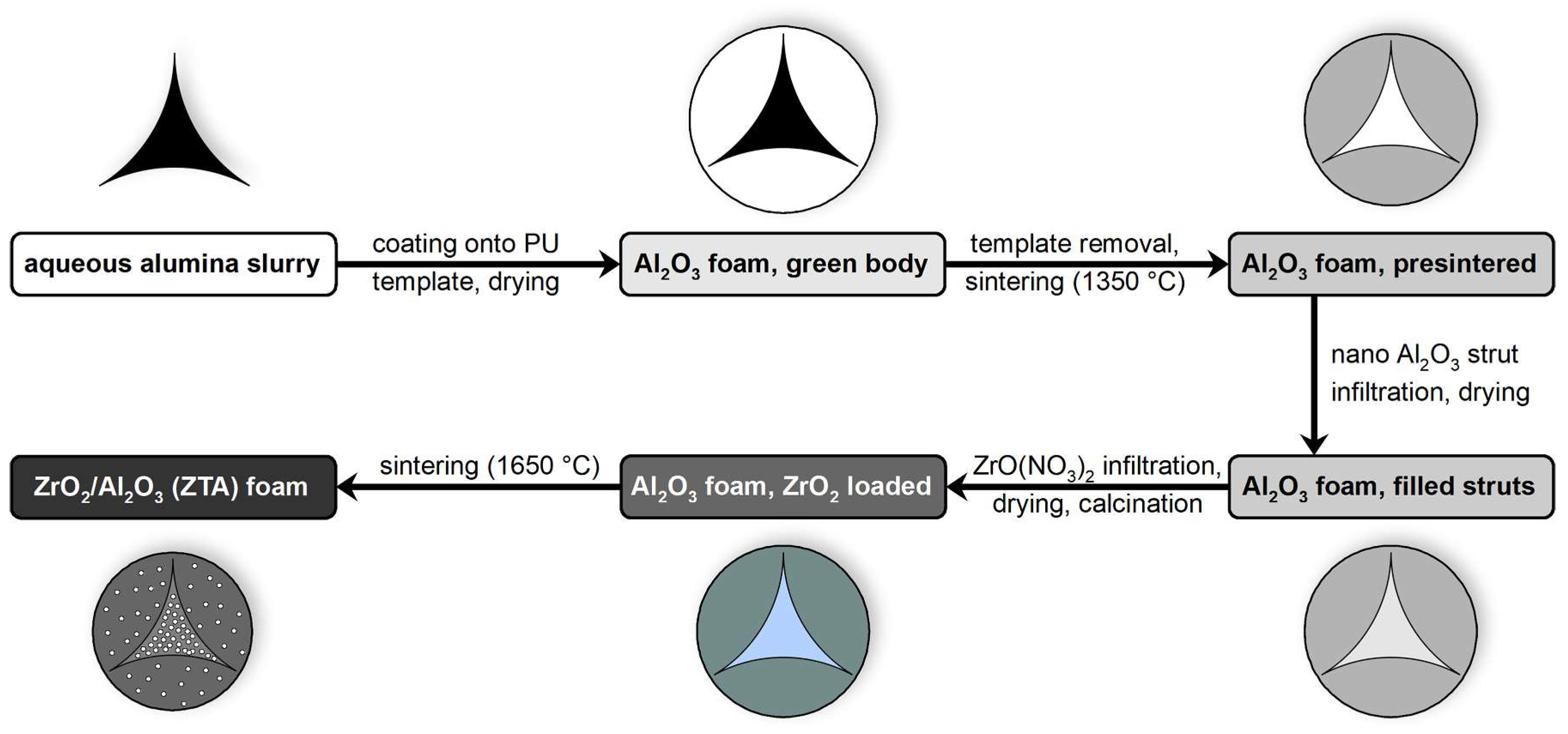

Reticulated polyurethane foam vs nano polyurethane. The cells that make up the foam can have a number of variations which can also be precisely controlled. From 10 pores per inch to 100 pores per inch this light weight foam is popular for filtration and is commonly referred to as filter foam. Reticulated metal foam can also be made using polyurethane foam as a template similar to its use in ceramic foams. Reticulated foams are used where porosity surface area low density are important.

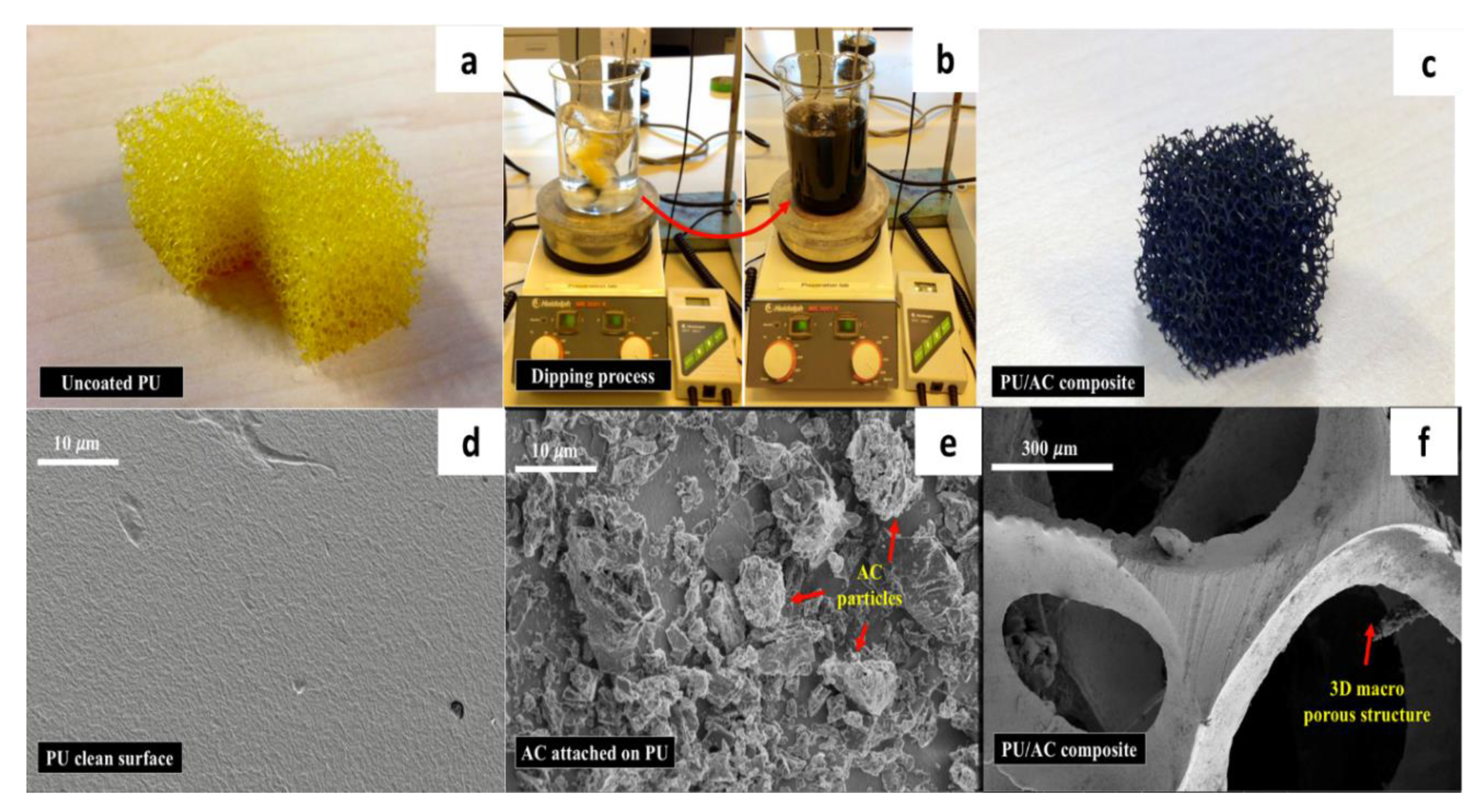

Reticulated polyurethane foam is a net like porous foam that is extremely versatile. A widely used and popular foam is the reticulated polyurethane. Reticulation is a post process in foam manufacturing that removes the window membranes of the cell. It offers superior solvency qualities a high viscosity rate and is resistant to abrasions as well as cutting.

It s typically used to make products that are involved in filtration sound absorption fluid management wiping and padding. Reticulated foams are open cell and have a wide range of porosity. Different foams have varying cell structures and characteristics. Typically 95 98 of cells are open in reticulated polyurethane foam.

Reticulated polyurethane foam is a versatile open cell material that is light weight low odor and highly resistant to mildew. Metals can be vapor deposited onto the polyurethane foam and then the organic polymer burned off.