S7 Tool Steel Hardness Range

S7 tool steel is a versatile formulation suitable for both cold and hot work service.

S7 tool steel hardness range. Sizes over 2 inches 63 5mm in cross section will not achieve full hardness by cooling in air. It is an air hardening material. Often made into chisels rivets and punches s7 tool steel can handle repeated impact without fracturing. It offers toughness to withstand chipping and breaking combined with high attainable hardness and good wear resistance.

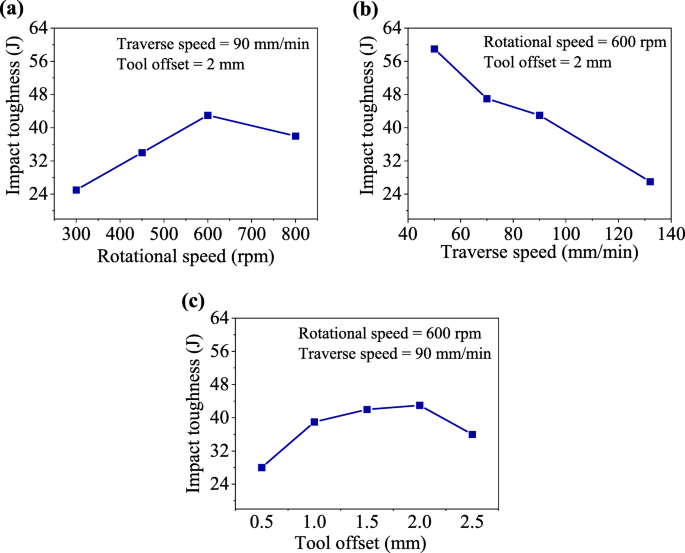

The diameter on these rods is precision ground while the straightness is held to a strict tolerance. Its charpy a test that measures the impact strength is over 200 ft lb. Also known as drill rod they are ready for turning in a lathe. It is necessary to increase the quench cooling rate between 1400 to 900 f 760 to 482 c by using.

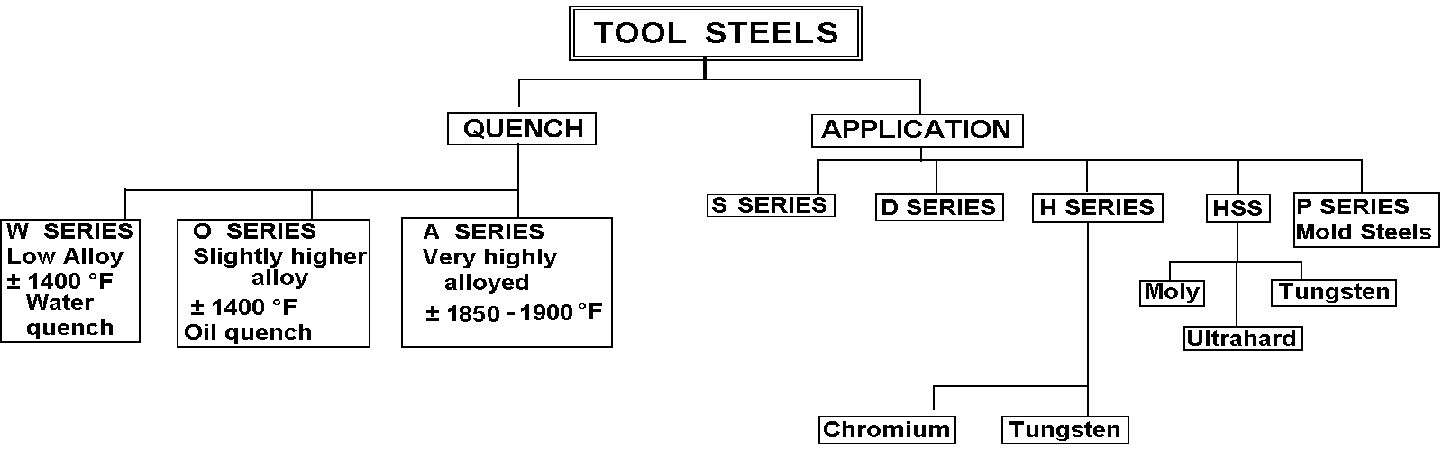

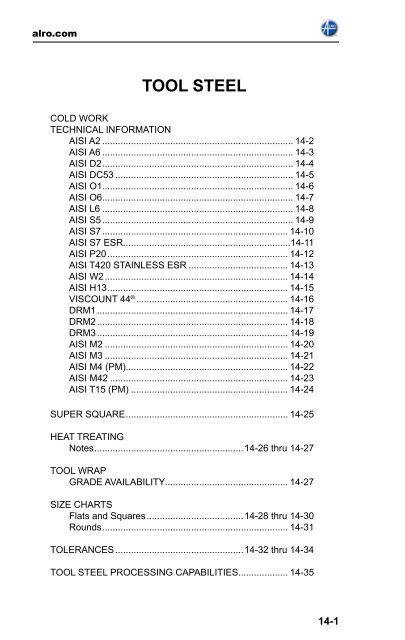

Additional material processing and application information for a wide range of tool steel types is available here. As an air hardening grade s7 is stable for heat treatment and its combination of high machinability and dimensional stability makes it ideal for a variety of different tool and. However the aisi sae tool steel code categorizes tool steels based on basic application and material characteristics. S7 tool steel is produced and supplied to the machinist or tool maker in the annealed or soft condition.

Crucible s7 aisi s7 crucible s7 is a shock resistant air hardening tool steel designed for high impact resistance at relatively high hardness. Or warm oil to 150 125 f 66 51 c. S 7 is typically heat treated and used in the rockwell c hardness range of rc 54 59.