Roll Form Tap Minor Diameter Chart

Technical information 262 966 2355.

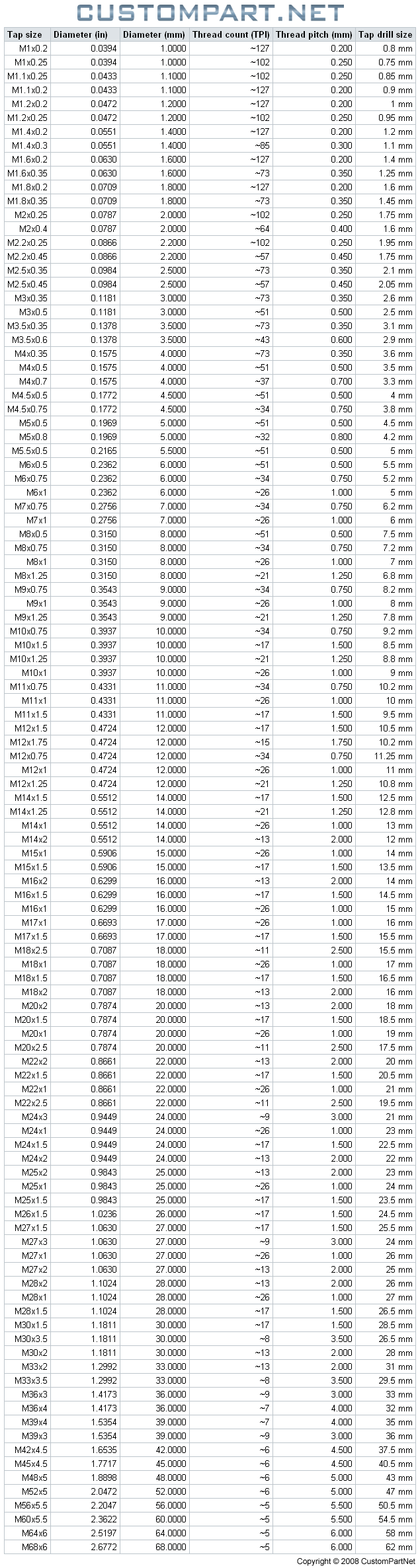

Roll form tap minor diameter chart. Metric external fasteners thread and fastener sizes m20 m50. We encourage all to build and buy american made. All dimensions are in millimeters. Chipless tapping stronger threads better thread gaging stronger taps longer tap life more efficient production and ideal for non lead screw tappers.

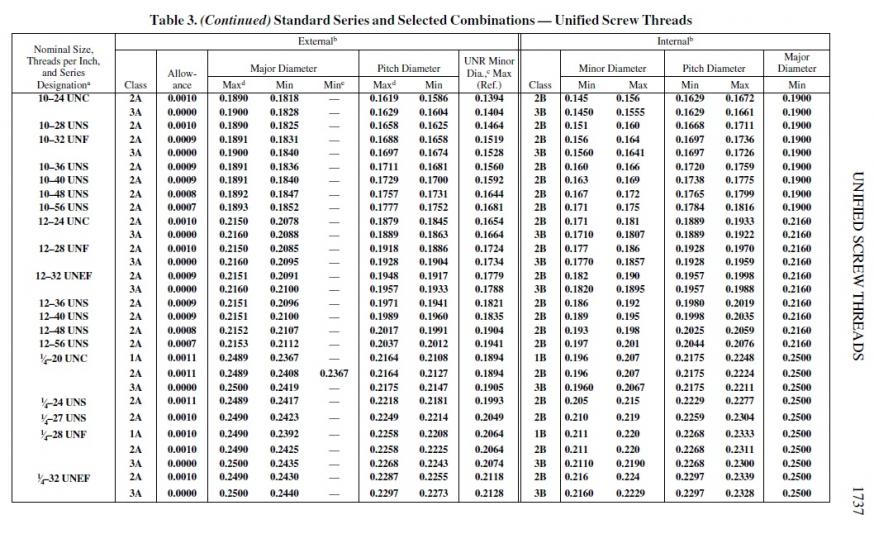

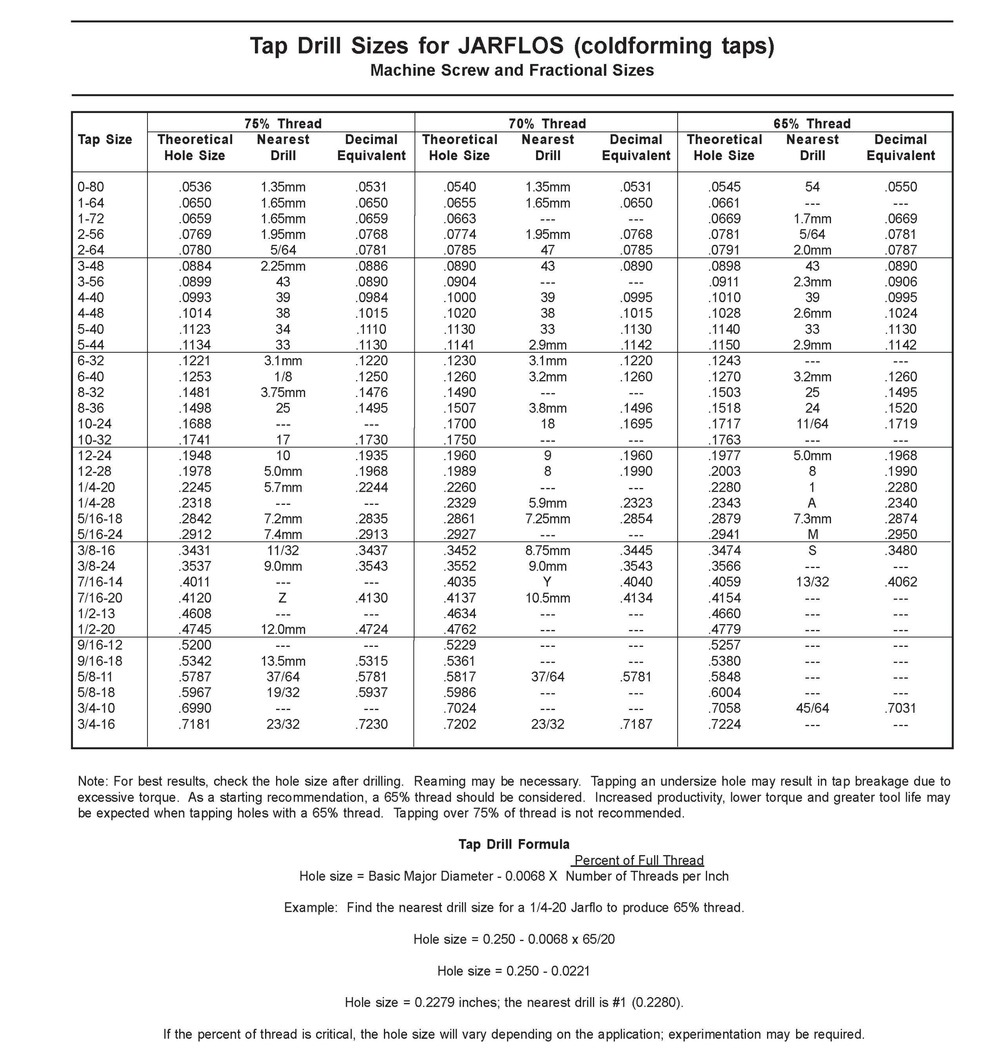

Ansi asme internal screw thread size chart. To establish tap drill sizes for inch size roll forming taps tap drill size basic tap o d. Form taps are used on aluminum brass copper lead stainless steel carbon steel cast steel leaded steel and zinc as well as other mild steels and medium alloys. Potential performance features in defined applications were simply wasted in the process.

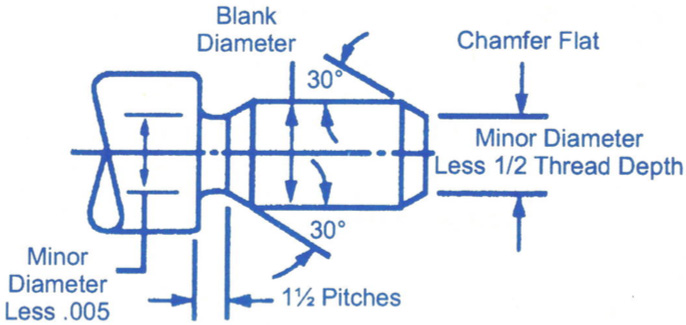

Blank dimensions pre tap hole sizes suggested tapping speeds surface treatments and thredfloer application data. Buying american made products benefits us all and makes the usa a stronger country. Technical support threading tapping drill size for thread forming. When roll tapping the diameter of the bored hole must be larger than the minor diameter of the internal thread because of the material deformation that occurs.

Drills generally cut holes larger than their diameters. Printable chart downloads at the bottom of the page. Emuge has made extensive investigations into the mechanisms of cold forming for years and developed an entirely new tool generation from the results. We support the made in the usa movement.

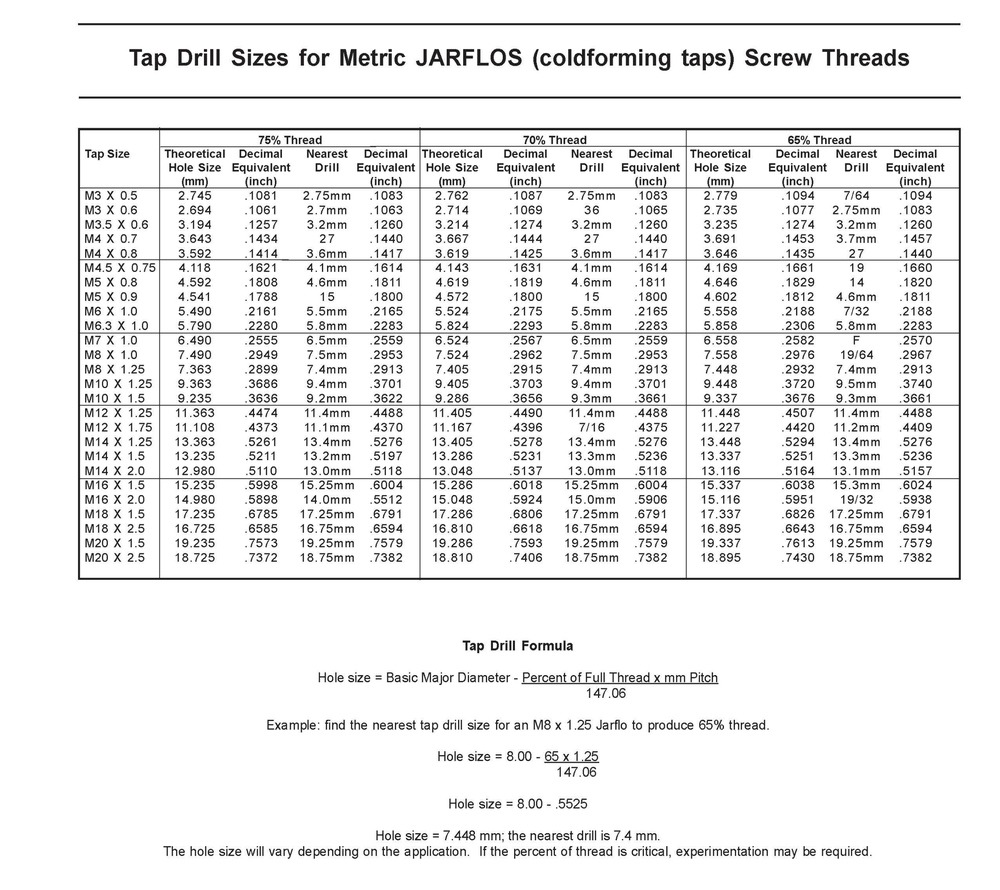

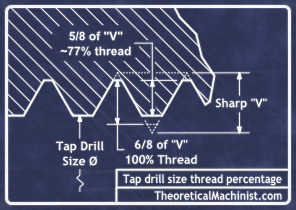

20 practical formula metric sizes to establish tap drill sizes for metric size roll forming taps tap drill size basic tap o d. Metric internal thread dimensions chart according to asme b1 13m metric screw threads. 0068 x of thread desired threads per inch example 1 4 20 tap with 65 thread 250 0068 x 65 228 dia. The new program is called.

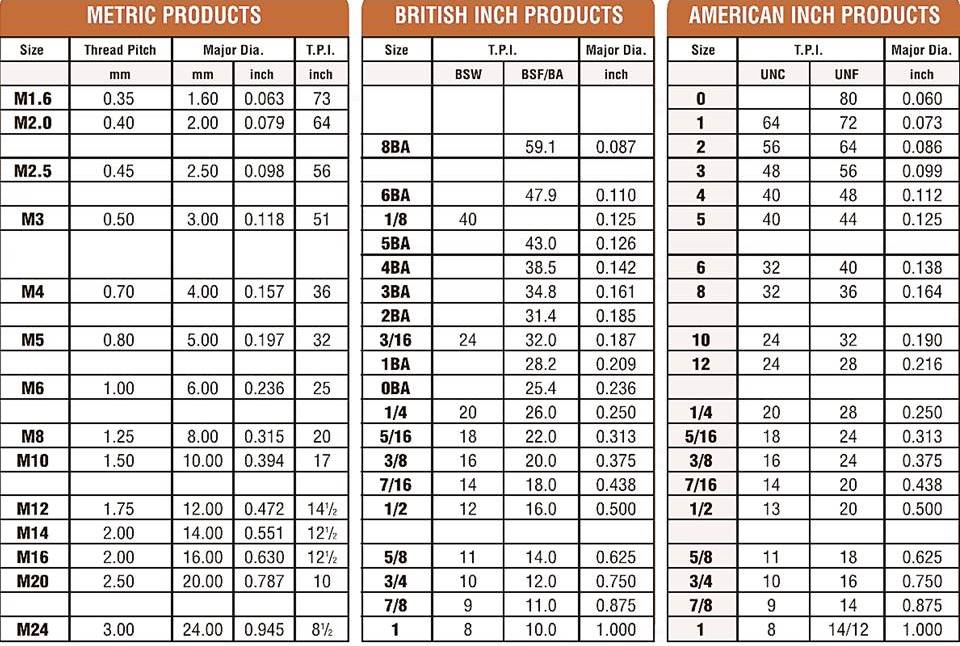

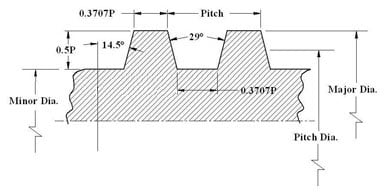

Conventional cold forming taps were made for the use in all ductile materials. All units are in inches. Screw thread designations minor diameter major diameter pitch diameter. We are proudly american made for 119 years.

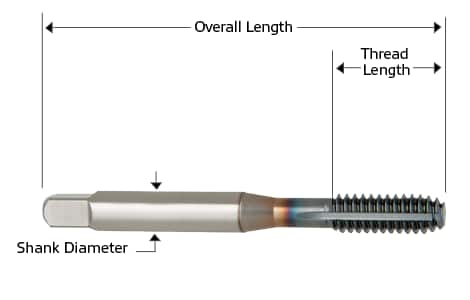

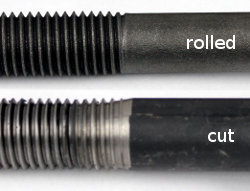

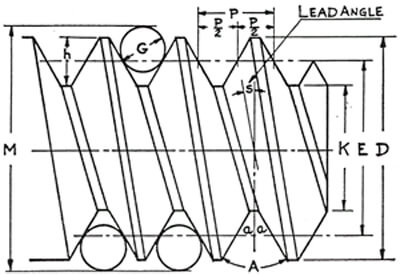

Thread forming taps are also known as fluteless taps form taps roll taps or cold forming taps they form threads by displacing material without producing chips. A minor diameter that provides a 55 to 65 thread is sufficient for most requirements but in some cases a higher percentage of thread may be necessary to conform with the minor diameter limits of the thread class specified. Ansi asme b1 1 1989 r2001 r2001 nomenclature are used. Minor diameter pitch diameter and major diameter are given dimensions in the internal thread chart.

Buy american for a better america.